About THREERISE

We boast a complete LED industry chain, encompassing LED lamps, PCB, IC, and modules. Our production base spans a total area of 10,000 square meters, with a building area exceeding 40,000 square meters and a workforce of over 100 employees.

At Threerise, we integrate a seasoned R&D team capable of rapidly transforming customer needs into innovative product solutions. Our experienced technical team empowers global projects, while our professional service team provides customers with comprehensive one-stop solutions, including consulting, planning, design, financing, construction, and maintenance.

Our domestic partners are spread across East China, North China, South China, Northeast China, and other regions, with over 150 partners and 1,000+ engineering collaborators. Internationally, our overseas partners span Europe, the United States, the United Kingdom, Oceania, the Middle East, and Asia, solidifying our global presence.

-

Corporate Vision

Building a New Era of Display Technology

-

Corporate mission

We relentlessly focus on customer needs by delivering diversified, high-performance display solutions that create sustainable value at every stage of our partnerships.

-

Core values of the enterprise

Shared accountability drives our co-creation process, ensuring all stakeholders equitably benefit from mutually prosperous outcomes.

Business philosophy

-

01 Product

R&D first

Material control

Equipment accuracy

Workmanship guaranteedProduct inspection

Senior teama

-

02 Plan

Demand analysis

Technology assessment

Design planning

Product choice

Cost estimate

-

03 Serve

Technical Support

Installation and debugging

After-sales service

Professional Training

-

04 Flow

Search Optimization

Social media marketing

Content marketing

Advertising

Factory Tour

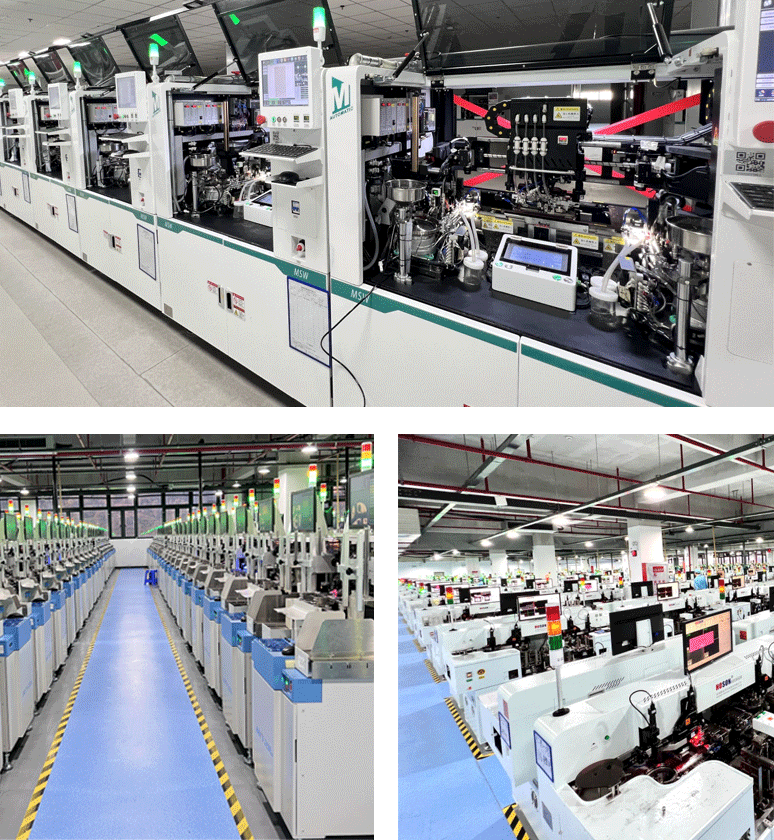

LED Module Manufacturing Base

Fully Automated Assembly - Robotic precision for consistent module quality

High-Speed SMT Process - 45,000 components/hour placement capability

Intelligent Quality Control - AOI+AI visual inspection system (99.98% accuracy)

Flexible Production - Quick changeover for various module sizes (P1.25-P2.5)

LED Lamp Manufacturing Base

Die Bonding: Mounting LED chips onto the substrate using silver paste or eutectic bonding technology.

Wire Bonding: Connecting the chip to electrodes with gold/copper wires, requiring high-precision equipment (e.g., ASM wire bonders).

Encapsulation: Filling with phosphor and silicone, which affects luminous efficacy and color temperature consistency.

Binning: Sorting based on parameters such as brightness, wavelength, and voltage to ensure batch uniformity.

PCB Manufacturing Base

Multi-layer board alignment accuracy of ±25μm meets stringent Mini/Micro LED requirements

High thermal conductivity metal substrate processing (aluminum/copper base)

Special flexible PCB processes (for bendable display applications)

Copper-filled via technology (supports high-current transmission)

Quality management

THREERISE Group steadfastly upholds the principle of "Premium Standards, Superior Quality, and Maximum Efficiency" in our relentless pursuit of quality excellence.

Quality Assurance System

We implement a comprehensive quality control framework that rigorously monitors every critical stage:

Raw Material Selection - Strict vendor qualification and material inspection protocols

Manufacturing Process - Automated production with real-time quality monitoring

Supply Chain Management - Full traceability system from components to finished products

Design Quality Assurance (DQA):

Our quality center operates independently and conducts independent, objective and impartial testing of the company's raw materials to ensure the reliability of product design quality.

Incoming Material Quality Assurance (QA):

Incoming Material Quality Assurance (QA): We control raw material production and supplier management from the source, and conduct strict reliability inspections on LED lamp beads, power supplies, modules, wires and other raw materials to ensure the reliable quality of incoming materials.

Process Quality Control (IPQC):

During the production process, we strictly follow the procedures of SMT, AOI, post-welding, three-proofing, glue filling, module aging, cabinet assembly, point-by-point correction, and cabinet testing, and perform The environment is controlled during the process to ensure the reliability of production.

Finished product quality inspection (FQC):

We conduct multiple tests on products such as high-temperature aging, vibration, salt spray, flushing, storm, pressure, and other outdoor product three-level tests to ensure the safety of product work.

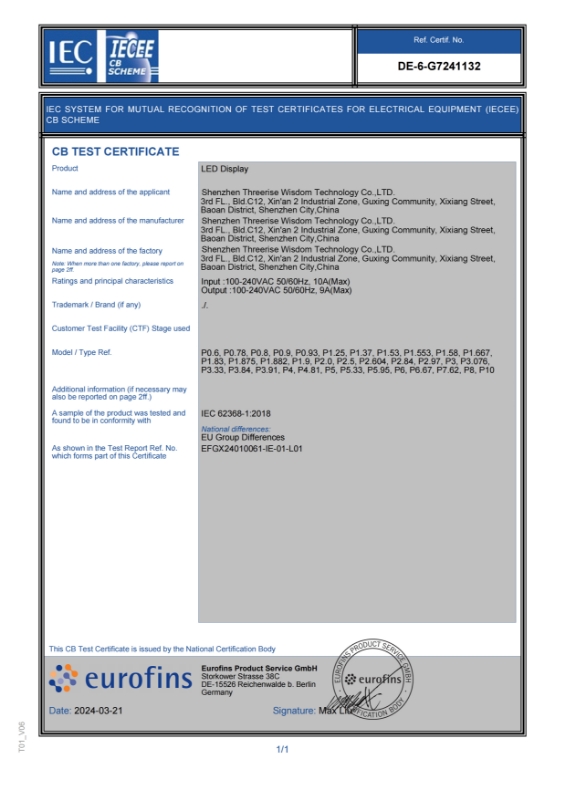

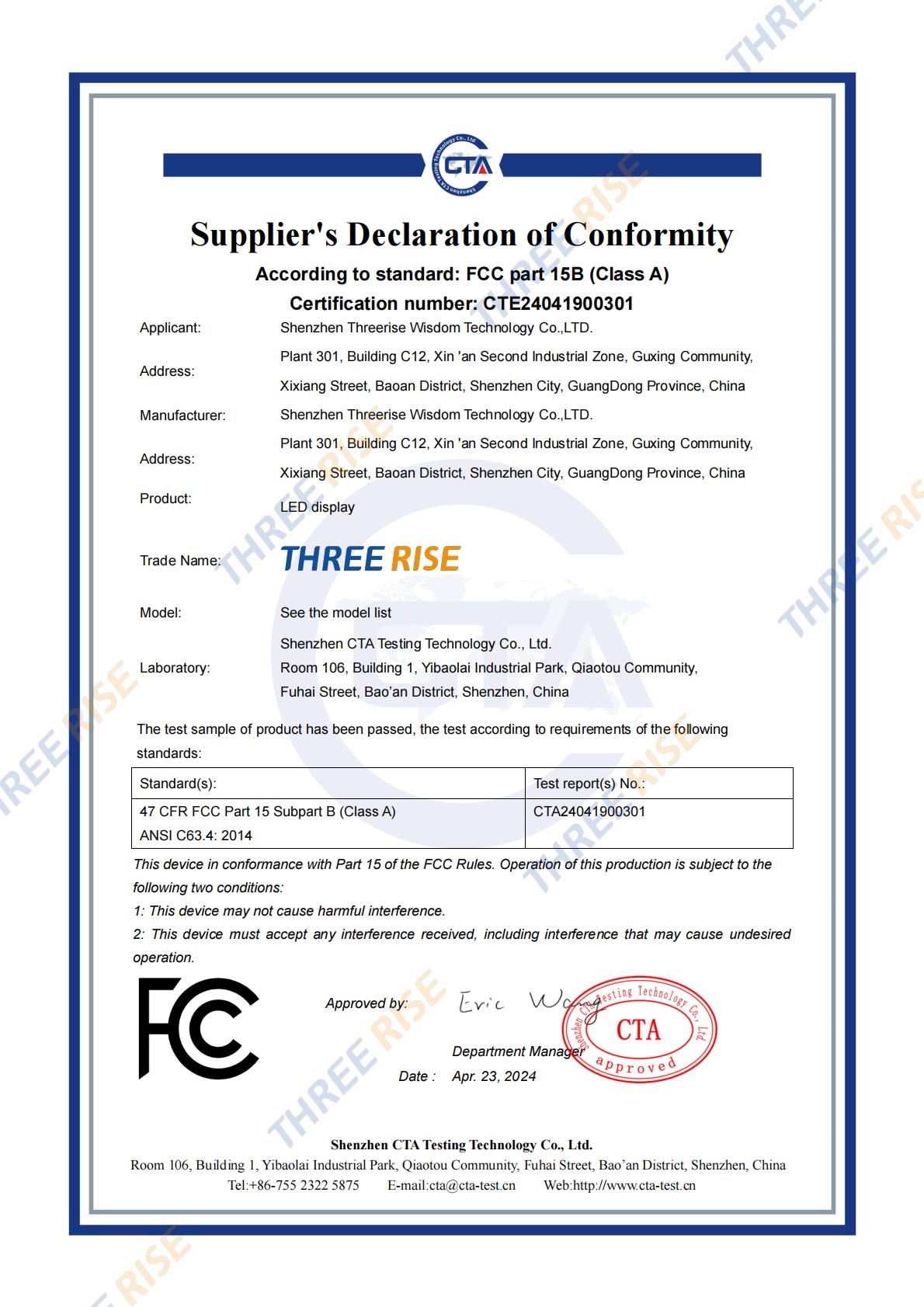

Certifications

-

CB

-

CE

-

FCC